BENTONITE FOR METALLURGY

While interacting with water, bentonite clay expands and becomes sticky.

This property allows to effectively use it as a binder for the production of pellets from iron ore concentrate (beneficiated wet nad crushed iron ore). Pellets are used in blast-furnace processing and electrometallurgical production. Their shape is optimal for efficient smelting into cast iron and direct iron production.

PELLET PRODUCTION INCLUDES TWO STAGES:

- Formation of wet granules of the required size from iron ore charge materials using the pelletizer;

- Sintering of these granules in kilns to such an extent that they can carry long-distance transportation, overloads, heating and smelting in furnaces.

Thus, bentonite acts not only as a bonding component, but also creates strong intergranular contacts that contribute to the reduction of cracks at high temperatures, giving strength to the pellets.

For the Mining and processing plants TAGBENT LLP offers the following products:

Activated bentonite clay with a full range of rheological properties necessary for pelletizing, agglomeration and briquetting technologies.

Activated dried bentonite clay is a dried product with preserved colloid-chemical properties, quality characteristics, and increased processability during unloading and storage in winter.

Bentonite powder is a dried and fine ground activated bentonite with preserved original physical and chemical properties.

Bentonite powder for chromite pellets is successfully used at Donskoy Mining and Processing Plant (“DGOK”) and Aktobe Ferroalloys Plant in the production of chromite pellets.

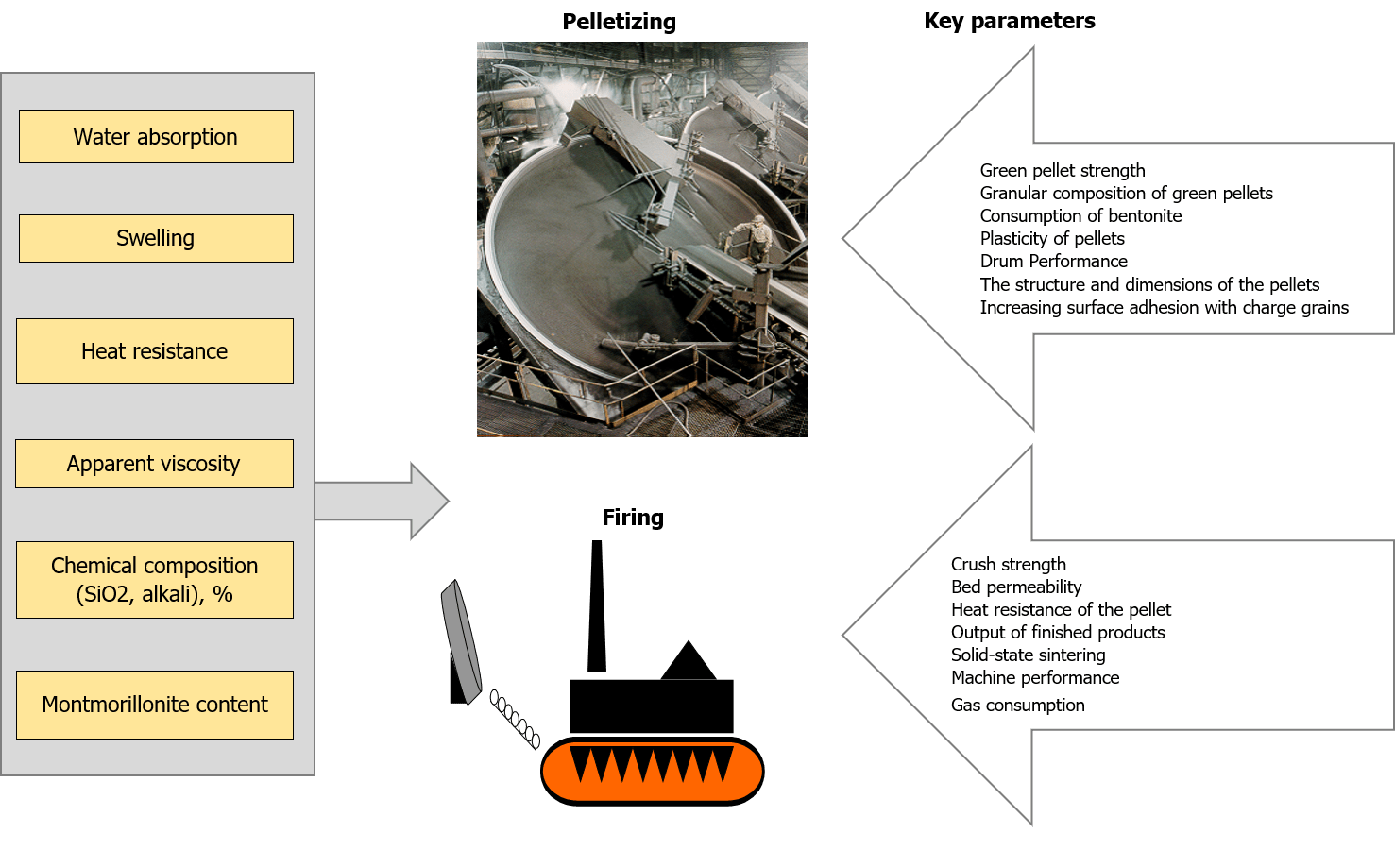

THE MOST IMPORTANT PROPERTIES FOR EVALUATING THE BENTONITE FOR USE IN PELLETIZING AND IRON AND STEEL PRODUCTION

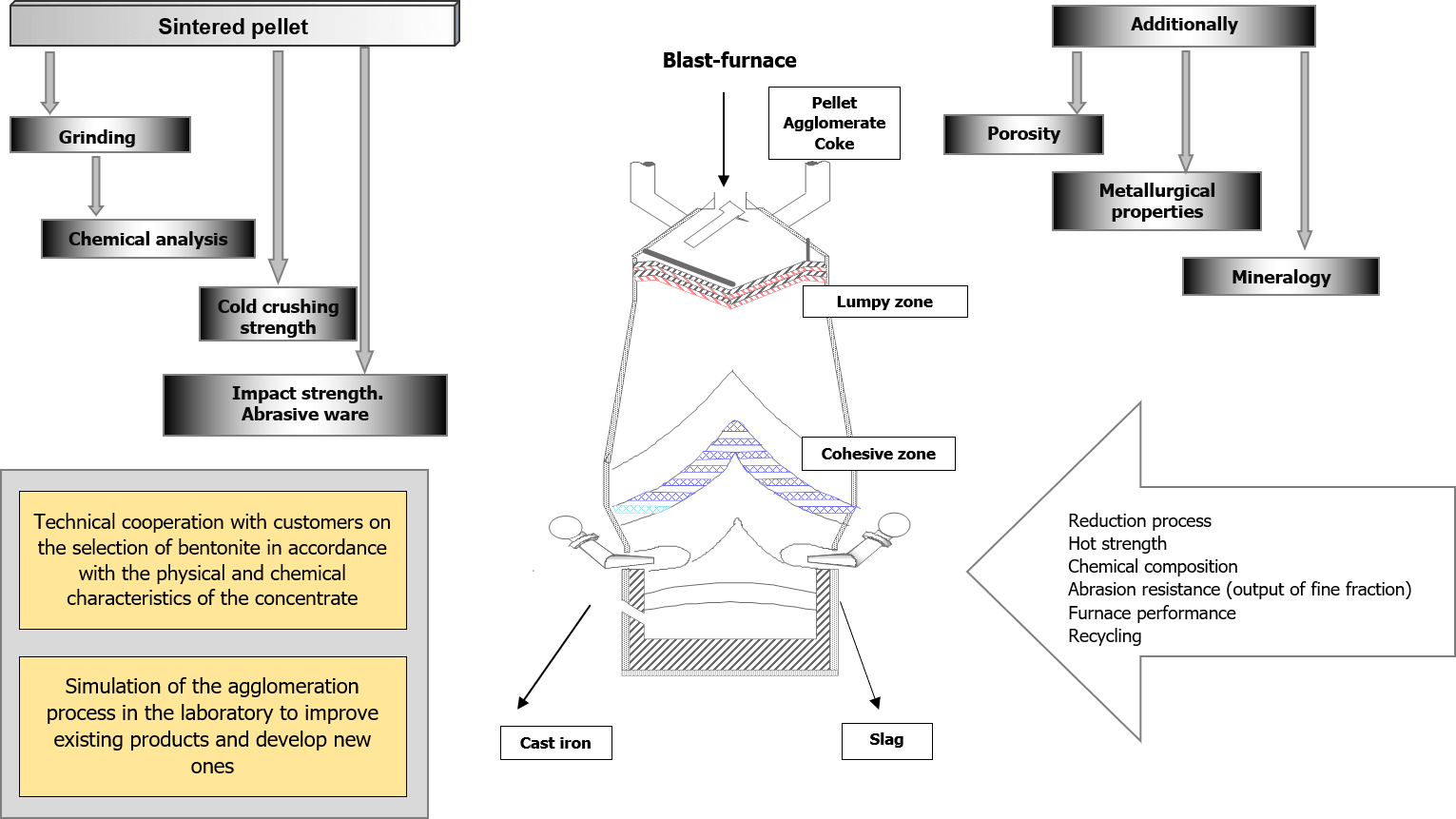

Cast iron and steel production

Effect of bentonite quality on pellet production

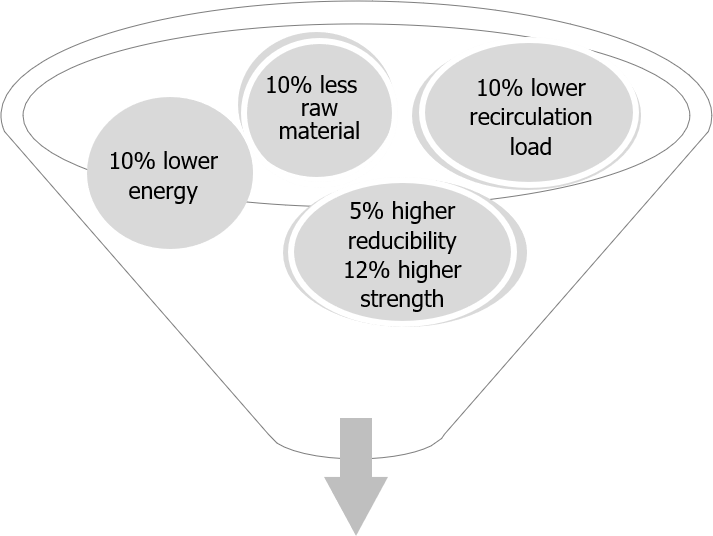

Depending on the concentrate and bentonite, the plant can achieve:

Bentonite quality is the key to PELLET Quality, Productivity and Cost

Our products add significant properties to customers’ products, including: thermal stability, strength, porosity, conductivity, opacity, durability, filtration, absorption, adsorption.

Bentonite is a clay characterized by fine dispersion, ion-exchange ability, high degree of swelling when moistened, cohesion, the ability to gradually release water when heated and increases the porosity of green pellets, which favorably affects the rate of moisture removal during pellet drying without reducing their strength.