BENTONITE FOR CRACKING CATALYST PRODUCTION

The unique combination of properties of clays of TAGBENT LLP, such as: low content of free sodium, low content of iron in the form of oxides, consistency of chemical and phase compositions, absence of harmful impurities – makes it possible to use clays from the Tagansky deposit to obtain mechanically strong oil cracking catalysts with high gasoline yield.

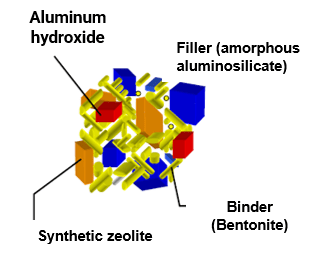

At present, zeolites synthetic crystalline aluminosilicate catalysts are used in oil refining catalytic cracking units. Bentonite clays serve in some cases as a binder in the production of aluminosilicate matrix of microspherical catalysts.

JSC “Gazpromneft – Omsk Oil Refinery” has developed a technology applying bentonite clay from the Tagansky deposit as a binding component of a strong aluminosilicate catalyst matrix. It is used in a total amount of about 20-25% of the catalyst (the rest is zeolite, aluminum hydroxide, amorphous aluminosilicate, spinel).